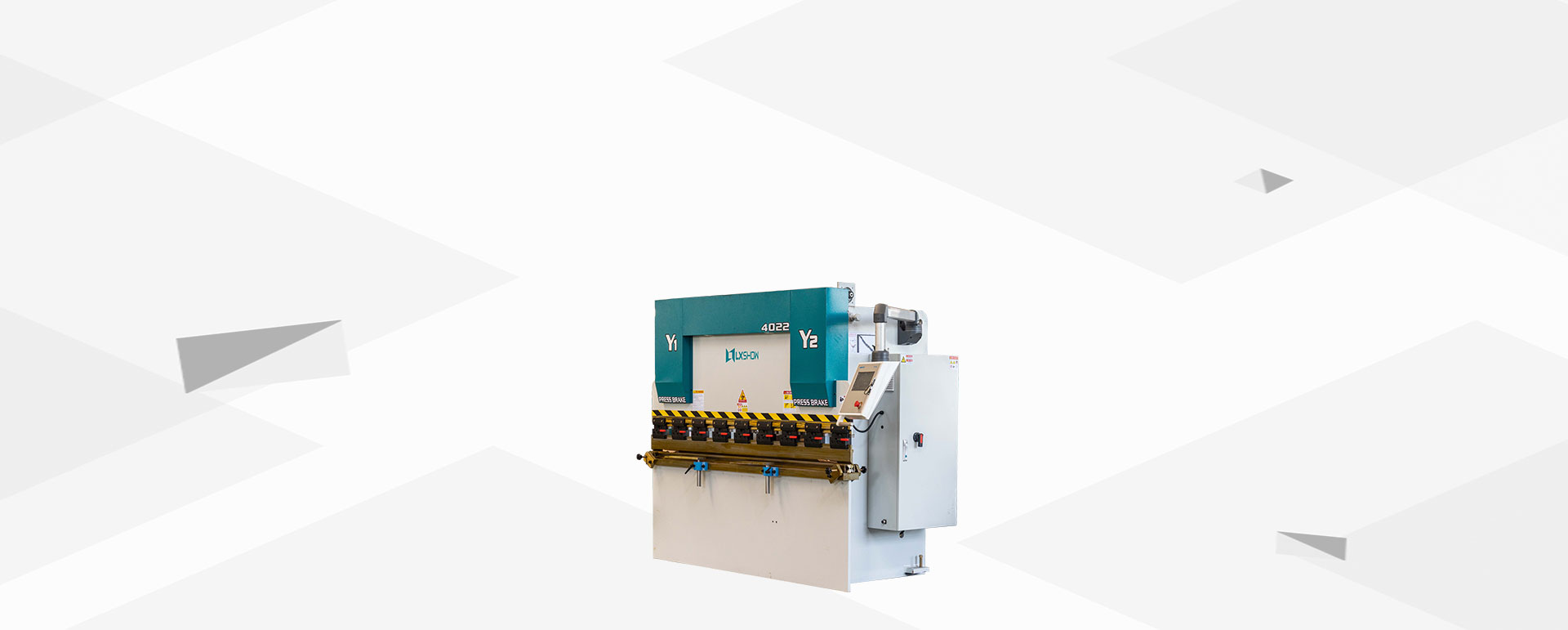

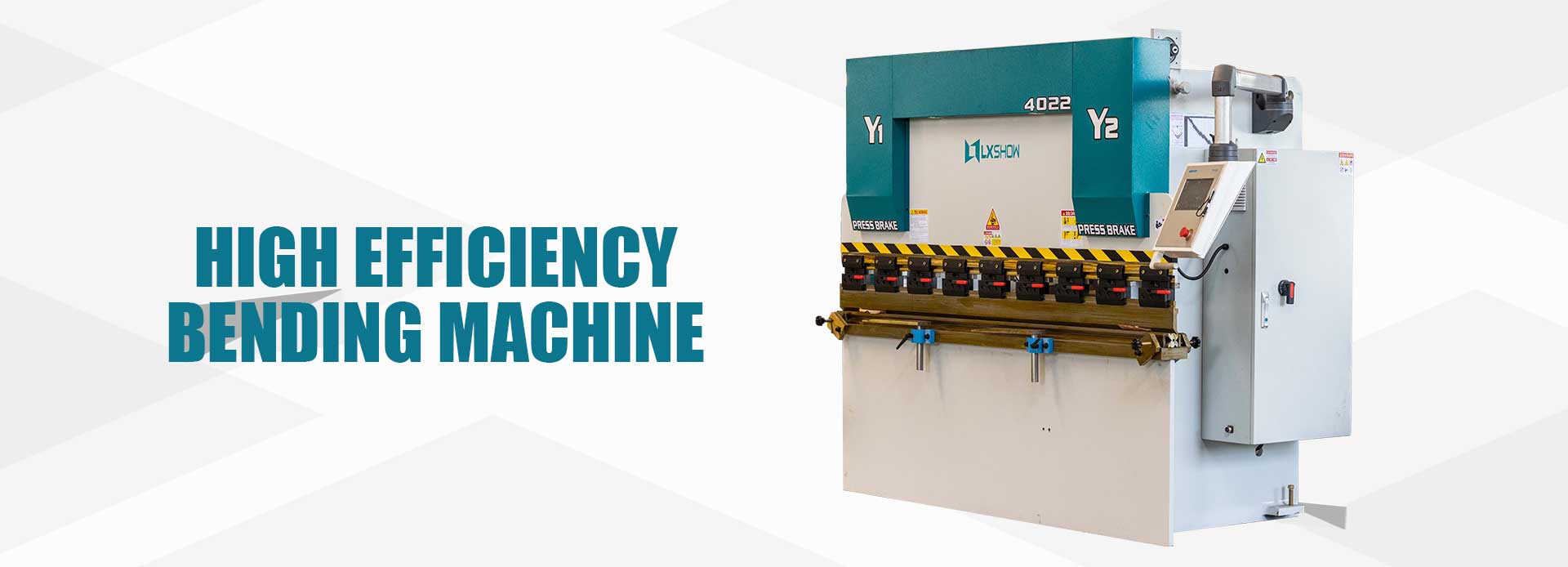

Likaroloana

•Sebopeho se feletseng se entsoeng ka tšepe, se nang le matla le ho tiea ho lekaneng;

•Sebopeho sa hydraulic down-stroke, se ka tšeptjoang le se boreleli;

•Yuniti ea ho emisa ea mechini, torque e tsamaellanang, le ho nepahala ho hoholo;

•Karolo e ka morao e sebelisa mokhoa oa ho lekanya mokokotlo oa sekurufu sa mofuta oa T ka thupa e boreleli, e tsamaisoang ke enjene;

•Sesebelisoa se ka holimo se nang le mokhoa o fokotsang khatello, E le ho netefatsa ho nepahala ho hoholo ha ho kobeha;

•Sistimi ea TP10S NC

Sistimi ea CNC

• Skrine ea ho ama ea TP10S

• Tšehetsa lenaneo la likhutlo le ho fetola mananeo a botebo

• Tšehetsa litlhophiso tsa hlobo le laeborari ea lihlahisoa

• Mohato o mong le o mong o ka beha bophahamo ba ho bula ka bolokolohi

• Sebaka sa ntlha ea ho chencha se ka laoloa ka bolokolohi

• e ka etsa hore Y1, Y2, R e atolosoe ka mekhahlelo e mengata

• Tšehetsa taolo ea tafole ea ho sebetsa ea mochini e koahelang moqhaka

• tšehetsa lenaneo le leholo la ho hlahisa arc e chitja ka boiketsetso

• Tšehetsa setsi se ka holimo se shoeleng, setsi se ka tlase se shoeleng, leoto le hlephileng, tieho le likhetho tse ling tsa ho fetola mehato, e ntlafatsa katleho ea ts'ebetso ka katleho

• Tšehetsa borokho bo bonolo ba electromagnet

• Tšehetsa mosebetsi oa borokho ba pneumatic pallet bo iketsang ka botlalo

• Tšehetsa ho kobeha ka boiketsetso, hlokomela taolo ea ho kobeha e sa laoleheng, 'me u tšehetse mehato e fihlang ho 25 ea ho kobeha ka boiketsetso

• Tšehetsa taolo ea nako ea ts'ebetso ea tlhophiso ea sehlopha sa li-valve, ho potlakisa lebelo, ho fokotsa lebelo, ho khutlisa, ho theola lebelo le ketso ea li-valve.

• e na le lilaebrari tsa lihlahisoa tse 40, laeborari e 'ngoe le e 'ngoe ea lihlahisoa e na le mehato e 25, selikalikoe se seholo se chitja se tšehetsa mehato e 99.

Sesebelisoa se ka Holimo sa ho Qetela

·Sesebelisoa sa ho tlama lisebelisoa se kaholimo se tlama ka potlako

Ho tlama ha Die ka Tlase ho Multi-V (khetho)

·Die e ka tlase ya Multi-V e nang le masoba a fapaneng

Sekala se ka morao

·Tataiso ea screw/liner ea bolo e nepahetse haholo

Tšehetso ea Ka Pele

·Sethala sa thepa ea alloy ea aluminium, ponahalo e ntle, le ho fokotseha ha ho qaptjoa ha mosebetsi.

Boikhethelo

Puseletso ea ho roesa meqhaka bakeng sa tafole ea mosebetsi

· Lekhapetla le kobehileng le na le sete ea likhapetla tse kobehileng tse nang le bokaholimo bo betlotsoeng. Lekhapetla le leng le le leng le hlahellang le entsoe ka tlhahlobo ea likarolo tse lekanyelitsoeng ho latela sekhutlo sa ho fapoha ha selaete le tafole ea mosebetsi.

·Sistimi ea taolo ea CNC e bala chelete e hlokahalang ea puseletso ho latela matla a mojaro. Matla ana a baka ho kheloha le ho fetoha ha lipoleiti tse otlolohileng tsa slide le tafole. 'Me a laola ka bohona motsamao o amanang oa wedge e kobehileng, e le ho lefella ka katleho ho kheloha ho bakoang ke slide le riser ea tafole, le ho fumana mosebetsi o loketseng oa ho kobeha.

Phetoho e Potlakileng Bottomm Die

·Amohela 2-v quick change clamping bakeng sa botlaaseng die

Molebeli oa Tšireletso ea Lasersafe

·Sesebelisoa sa ho sireletsa sa PSC-OHS sa laser, puisano pakeng tsa molaoli oa CNC le mojule oa taolo ea polokeho

· Mahlasedi a mabedi a tswang tshireletsong a na le ntlha e ka tlase ho 4mm ka tlase ho ntlha ya sesebediswa se ka hodimo, ho sireletsa menwana ya mosebedisi; dikarolo tse tharo (ka pele, bohareng le tsa sebele) tsa mohiri di ka kwalwa ka bonolo, ho netefatsa hore tshebetso e rarahaneng ya ho kobeha ha lebokose e a kwalwa; ntlha e kgutsitseng ke 6mm, ho etsa tlhahiso e sebetsang hantle le e bolokehileng.

Thuso ea ho Koba Servo ea Mechini

· Ha poleiti ea tšehetso ea ho kobeha letšoao e ka hlokomela mosebetsi oa ho reteleha ho latela. Sekhutlo le lebelo tse latelang li baloa le ho laoloa ke molaoli oa CNC, li tsamaee ka tataiso e otlolohileng ka letsohong le letšehali le le letona.

· Fetola bophahamo ho ea holimo le tlase ka letsoho, ka pele le ka morao le hona ho ka fetoloa ka letsoho ho lekana bakeng sa ho buloa ha die tse fapaneng tsa tlase

·Sethala sa tšehetso e ka ba borashe kapa tšepe e sa hloekang, ho latela boholo ba mosebetsi, ho ka khethoa motsamao oa khokahano ea litšehetso tse peli kapa motsamao o arohaneng.

Paramethara ea Mochini oa ho Koba Tšepe

| Mofuta oa sesebelisoa sa mochini | WG67K-40T/2200 | |

| Matla a tloaelehileng | 400 kN | |

| Bolelele ba ho kobeha | 2200mm | |

| Sebaka se pakeng tsa likholomo | 1600 mm | |

| Botebo ba 'metso | 230 mm | |

| Bolelele bo bulehileng | 320 mm | |

| Motsamao oa seterata | Setorouku | 100mm |

| Lebelo le potlakileng la ho theoha | 100mm/s | |

| Lebelo la ho kgutla | 85mm/s | |

| Ho potlakisa mosebetsi | 10mm/s | |

| Ho nepahala ha motsamao oa seterata | Ho nepahala ha sebaka | ± 0.03mm |

| Ho nepahala ha boemo bo pheta-phetoang | ± 0.02mm | |

| Matla a maholo a enjene | Matla | 5.5 KW |

| Sistimi ea taolo ea linomoro | Mohlala | Sistimi ea TP 10S |

| Liparamitha | ||||||

| Mohlala | Boima ba 'mele | Bophara ba Silindara sa Oli | Sekoti sa Silindara | Lebota la lebota | Seterata | Plate ea Mosebetsi ea Pampeng e ka Holimo |

| WG67K-30T1600 | Lithane tse 1.6 | 95 | 80 | 18 | 20 | 20 |

| WG67K-40T2200 | Lithane tse 2.1 | 110 | 100 | 25 | 30 | 25 |

| WG67K-40T2500 | Lithane tse 2.3 | 110 | 100 | 25 | 30 | 25 |

| WG67K-63T2500 | Lithane tse 3.6 | 140 | 120 | 30 | 35 | 35 |

| WG67K-63T3200 | Lithane tse 4 | 140 | 120 | 30 | 35 | 40 |

| WG67K-80T2500 | Lithane tse 4 | 160 | 120 | 35 | 40 | 40 |

| WG67K-80T3200 | lithane tse 5 | 160 | 120 | 35 | 40 | 40 |

| WG67K-80T4000 | Lithane tse 6 | 160 | 120 | 35 | 40 | 45 |

| WG67K-100T2500 | lithane tse 5 | 180 | 140 | 40 | 50 | 50 |

| WG67K-100T3200 | Lithane tse 6 | 180 | 140 | 40 | 50 | 50 |

| WG67K-100T4000 | Lithane tse 7.8 | 180 | 140 | 40 | 50 | 60 |

| WG67K-125T3200 | Lithane tse 7 | 190 | 140 | 45 | 50 | 50 |

| WG67K-125T4000 | Lithane tse 8 | 190 | 140 | 45 | 50 | 60 |

| WG67K-160T3200 | Lithane tse 8 | 210 | 190 | 50 | 60 | 60 |

| WG67K-160T4000 | Lithane tse 9 | 210 | 190 | 50 | 60 | 60 |

| WG67K-200T3200 | lithane tse 11 | 240 | 190 | 60 | 70 | 70 |

| WC67E-200T4000 | Lithane tse 13 | 240 | 190 | 60 | 70 | 70 |

| WG67K-200T5000 | lithane tse 15 | 240 | 190 | 60 | 70 | 70 |

| WG67K-200T6000 | Lithane tse 17 | 240 | 190 | 70 | 80 | 80 |

| WG67K-250T4000 | lithane tse 14 | 280 | 250 | 70 | 70 | 70 |

| WG67K-250T5000 | Lithane tse 16 | 280 | 250 | 70 | 70 | 70 |

| WG67K-250T6000 | Lithane tse 19 | 280 | 250 | 70 | 70 | 80 |

| WG67K-300T4000 | lithane tse 15 | 300 | 250 | 70 | 80 | 90 |

| WG67K-300T5000 | Lithane tse 17.5 | 300 | 250 | 80 | 90 | 90 |

| WG67K-300T6000 | lithane tse 25 | 300 | 250 | 80 | 90 | 90 |

| WG67K-400T4000 | lithane tse 21 | 350 | 250 | 80 | 90 | 90 |

| WG67K-400T6000 | lithane tse 31 | 350 | 250 | 90 | 100 | 100 |

| WG67K-500T4000 | Lithane tse 26 | 380 | 300 | 100 | 110 | 110 |

| WG67K-500T6000 | lithane tse 40 | 380 | 300 | 100 | 120 | 120 |

Pontšo ea Mohlala le Indasteri

Sephutheloana

Feme

Tšebeletso ea Rōna

Ketelo ea Bareki

Mesebetsi e seng inthaneteng

LBH

P: Na o na le tokomane ea CE le litokomane tse ling bakeng sa ho hlakola thepa ea lekgetho?

A: E, re na le CE, re u fa tšebeletso ea ho emisa hang.

Qalong re tla o bontsha mme kamora ho romelwa re tla o fa CE/Lenane la ho paka/Invoice ya Kgwebo/Konteraka ya Thekiso bakeng sa ho hlwekisa thepa ya lekgetho.

K: Na o ka mpolella thepa ea hau: cs kapa ss le botenya ba tsona? Le bophara bo boholo ka ho fetisisa ba ho kobeha? Ebe ke tla u tiisetsa mohlala oa mochini.